Kompaktowe i szybkie suszenie

Suszarnia Pneumatyczna, zwana również Drymeister (DMR)

Suszarnia pneumatyczna Drymeister łączy suszenie, mielenie i klasyfikowanie w jednej instalacji. Drymeister może przekształcać

The Drymeister flash dryer combines drying, milling and classifying in a single installation. The Drymeister can transform damp feed material into an ultrafine powder with an extremely narrow particle size distribution in a matter of seconds. This makes the equipment an economical alternative to spray and other dryers.

In order to produce dry powders competitively from wet processes it is crucial to save energy at every opportunity. The best way to achieve this is to keep the quantity of water to be evaporated as low as possible. Thermal drying is by its nature far more energy intensive than mechanical dewatering. The first phase of the drying process is therefore usually either centrifuging or filtration. The mechanically dewatered product will then require further drying. Considerable variation is found in the composition of products to be dried, depending on such factors as the size, form and solubility of the particles. In practice this ranges from viscous slurries to friable filter cake.

Thermal drying

The selection of the appropriate drying process depends on a complex mix of factors. The nature of the product to be dried plays an important role, but the available space, the downstream processes and the conventions of the relevant market are also significant issues. If the choice is for flash drying (as opposed to belt drying for example), there is a further selection to be made between the different systems available. Two familiar forms of flash drying are ring drying (or pneumatic drying) and spray drying.

Ring and spray drying

In ring drying the product to be dried is injected into a hot stream of air. The product dries instantaneously and is then separated out of the drying air in a cyclone. It is possible to add a portion of the dried product to the wet feed in order to optimalise the drying process. In a spray dryer a layer of viscous slurry at the top of a tower is atomised using pressure nozzles or finely divided using compressed air or a mechanical wheel. The droplets dry during their fall to form small particles which are captured and taken off from the base of the tower. This drying method requires a certain degree of fluidity in the slurry to be dried. It may even be necessary to add water to the slurry to improve atomisation. It will be clear to the reader that the process of mechanical dewatering followed by diluting to allow subsequent drying is highly wasteful of energy.

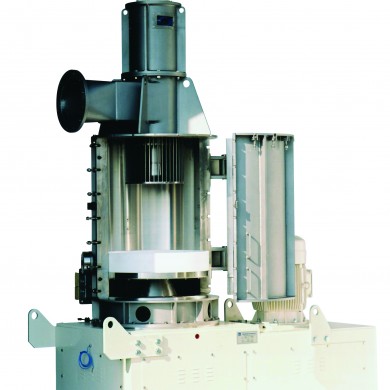

Drymeister (DMR)

A far better approach is to immediately dry the product further, even in the case of friable filter cake. Hosokawa Micron developed the Drymeister flash dryer to meet this need, with a technology combining drying, milling and classifying in a single installation. Various options are available for feeding the Drymeister, for example a twin screw conveyor. The product is taken into a milling chamber where a rotor reduces the particle size of the material. This produces a large contact area, allowing rapid drying. A hot stream of air fluidises and dries these particles. The dry, light particles are carried up into the airflow and are able to pass the classifier wheel at the top of the installation. The still wet and therefore heavier particles will fall back into the drying chamber until they are also dry. The particles taken up by the drying air are separated out of the airstream, for example using a cyclone or filter installation. Within a matter of seconds the Drymeister can transform a damp feed material into an ultrafine powder with a very narrow particle size distribution.

Process parameters

Various process parameters can be modified to control the performance of the Drymeister. For example the speed and temperature of the hot airstream can be modified (up to 650°C) based on the outlet temperature. The final moisture content of the particles can also be modified by changing the revolution speed of the classifier wheel. Another adjustable process parameter is the revolution speed of the milling rotor. A range of different rotors can be used, depending on the constitution of the product to be dried. This can also prevent build-up of product in the milling chamber. The performance of the Drymeister can therefore be optimalised to the requirements of each specific application, while a single machine can be used to dry a succession of quite diverse products. The Drymeister is easily accessible for cleaning, inspection and maintenance. The installation is also very compact compared to other drying systems of comparable capacity.

Exponential

The Drymeister is not only ideal for new drying processes, it has also proved itself as a time and energy-saving alternative to existing spray dryers. This ties in with its capacity to dry products with a high solid matter content. The importance of this will become clear when one considers that the quantity of water to be evaporated increases exponentially with the moisture content of the product. This can be shown by a calculation. To obtain 100 kg of dry powder from a product with a moisture content of 60%, 150 kg of water must be evaporated. If the product has a moisture content of 20% however, only 25 kg of water must be evaporated for 100 kg of dry powder.